We purchased an old Reynolds Aluminum solar hot water heater from someone who removed it when they replaced their roof. It was not running but restorable. All major components were there and repairable except for the hot water tank. That was replaced with a standard 80 gallon electric hot water heater. Below: Front of panel removed from housing. Above: Rear of panel, with Jack standing guard.

We purchased an old Reynolds Aluminum solar hot water heater from someone who removed it when they replaced their roof. It was not running but restorable. All major components were there and repairable except for the hot water tank. That was replaced with a standard 80 gallon electric hot water heater. Below: Front of panel removed from housing. Above: Rear of panel, with Jack standing guard.

The panels each had a pinhole leak, and tons of auto radiator stop leak inside the tubes. After flushing them out, I soldered the holes with aluminum solder. A tricky operation, since the melting point of the solder is just slightly lower than the aluminum panel. I used a torch to heat the panel while using an electric iron to melt the solder. It is a very strong repair.

The Reynolds was a well engineered system with everything contained within the circular heat exchanger. It is very compact, yet not difficult to maintain.

VIDEO Guide: A Prepper’s Guide in Safeguarding a Home

Below: A picture of what is inside. The red pump on the left is the antifreeze pump, and has a cast iron body. The gold pump is the fresh water pump, and is stainless steel. They are both original Grundfos pumps, and are very well made. Behind the pumps is the expansion tank. Above that is a sight-glass I added. It lets me see the antifreeze and whether it is flowing.

The next step was to run 5/8″ aluminum tubing from the basement to the roof. I ran it up the outside wall, hiding the insulated tubing inside aluminum rain spouts to match the house. It looks like an additional downspout and is not very noticeable.

The original aluminum fittings are of a type I have not seen anywhere else. The ones on my system were no longer usable, so I replaced them with aluminum AN style aircraft fittings. I also bought the tubing from an aircraft supply house. Here is a picture of an AN fitting:

They are flare fittings, which of course requires the tube to be flared using a flaring tool. Flare fittings are extremely reliable, which is why they are used on airplanes and critical things like auto brake lines.

Even though the panels are a prominent feature on the rear of the house, they are nearly invisible from the front.

I believe there are many of these systems sitting unused on roofs around the country. I missed out on getting another one by mere hours. I knew of a house with one of these systems and had considered stopping and asking them about it. Then one day, I went by and they were getting a new roof. Unfortunately, the panels were already scrapped! These well designed systems still have life in them and deserve to live a few years longer.

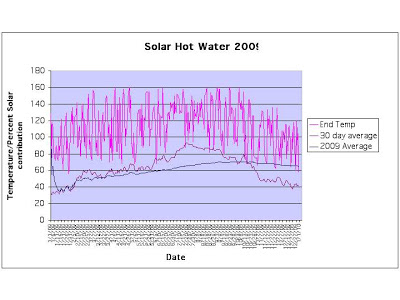

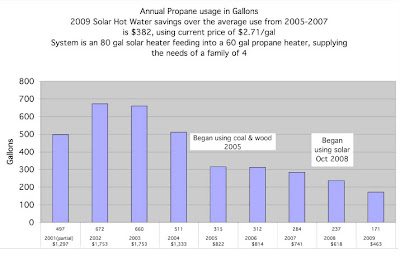

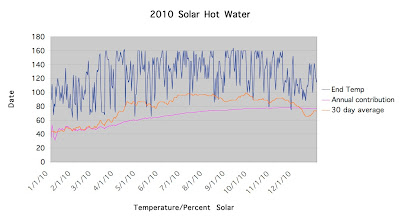

UPDATE: 2010 was an even better year for the system, with a few months approaching 100% solar, and a yearly average of 76%. I switched the backup source of hot water from propane to electric when my propane heater failed. I decided that the old fashioned tank style heater with a pilot light is too inefficient, and tank-less ones too expensive. It was far more cost effective to install an inexpensive 60 gallon electric as the backup. This has worked out well, for I still have monthly electric bills that are very low, if not zero. See my Solar Electric Upgrade post for charts on electricity production.

My propane usage dropped so low that my former propane company no longer wants my business.

UPDATE 2012: I compiled 3 years worth of daily records and put them into a new post.

The system has now been operating for over 4 years, and has required nothing more than a gallon of antifreeze over that time. I stopped taking daily records, figuring that 3 years worth was sufficient to prove the value of these systems. Given my 3 year average of nearly 2,000 hours of operation, I estimate that it has nos surpassed 9,000 hours. If these are original pumps, they may have 50,000 hours of total running time.

UPDATE 2014: The system has now been in operation over 5 years, and has paid for itself twice over. The automotive heater hose that is used to connect the panels to the pipes failed. Their lifetime is much shorter in the severe conditions of a solar heater than it is in an automobile. I recommend replacing them every four years. The panels, pumps, and heat exchanger all look like they have many years of life left in them.

RECOMMENDED ARTICLE: DIY project – Building a Root Cellar

Self-sufficiency and Preparedness solutions recommended for you:

The Lost Ways (The vital self-sufficiency lessons our great grand-fathers left us)

Survival System (Learn The 7 Secrets Every Family Must Know To Survive Any Disaster Or Crisis)

Stockpile Challenge (So what’s the recipe for “getting lucky” in the coming catastrophe?)

Food for Freedom (If I want my family to survive, I need my own food reserve)