This is a project that was built mostly from materials that we had on hand. We’ve used it for the past 2 summers with excellent results. The design is a small scale version of a commercial dehydrator and can be adapted to use whatever materials that are available to you. The photos below should explain the bulk of the details but please leave a comment or email if you have any questions.

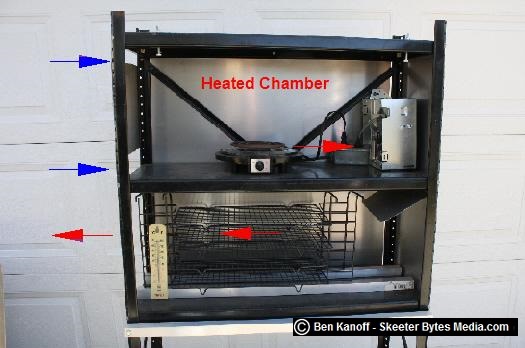

The dehydrator functions by drawing air into the heated top chamber with a low-volume fan and pushing the heated air into the bottom chamber and across the food to be dehydrated.

The foundation for this dehydrator is a small metal storage shelf, the dimensions are approximately 30″W x 12″ deep x 60″ tall. It was covered with .060″ aluminum sheet. The back and right side were completely covered. The front aluminum panel is removable and the left side was only partially covered, as shown in the photo below.

How to Make Jerky With and Without a Dehydrator

How to Extract Water from a Water Heater When SHTF

The top chamber houses the heat source and the fan. The heat source for this dehydrator is a hot plate with adjustable heat. The fan is a bathroom fan purchased at Lowes for about $10.00. A hole was cut in the shelf for the fan’s outlet flange and the fan was bolted directly to the shelf. An aluminum deflector was also bolted in place to direct the warm air across the food racks.

The bottom chamber houses the food racks and a thermometer. The food racks are cookie cooling racks purchased at Target. The rack stand was fabricated from scrap aluminum tubing and a condiment basket from our LP grill. The thermometer is necessary to help regulate the temperature for proper dehydration.

We use this dehydrator to take advantage of the low prices of fresh local produce and some of the excess from our gardens. It works much better and is more “controllable” than the round plastic vertical flow dehydrators. Normally, a Med/Low setting on the hotplate will keep the bottom chamber at 140 degrees.

Some technical details for the “off-grid” folks:

- The fan is 59CFM and draws about 100 watts

- The hotplate draws 750 watts intermittently. It isn’t on constantly, especially when set on a low/med setting depending on ambient temps.

We’ve discovered that we can actually use 2 of the round plastic dehydrators on top of this dehydrator without even plugging them in. Once this dehydrator is warmed up, there’s enough heat on the top shelf to use in the process that otherwise would have been wasted. We use the round dehydrators as a staging area for food waiting to go into the bottom chamber. That is a bonus feature that wasn’t expected and basically triples the output without any additional electricity required!

This dehydrator was built from items that we had sitting in our shop. The only items that were purchased specifically for the dehydrator were the fan and the cookie racks. You could easily adapt this design to any metal shelving unit. I also believe that you could wrap the shelves in plywood or galvanized metal instead of aluminum if necessary. Ideally, the project should cost much less than an Excalibur dehydrator.

There are a few cosmetic issues that we plan to take care of this winter. A couple of handles on the front access panel and a permanently installed thermometer would be nice as well as an external junction box with an on/off switch for the fan.

Recommended:

Recommended:

Self-sufficiency and Preparedness solutions recommended for you:

Lightsoutusa (You will have communications in ANY TYPE of disaster.)

Survival MD (Knowledge to survive any medical crisis situation)

Survival System (Learn The 7 Secrets Every Family Must Know To Survive Any Disaster Or Crisis)

Survive After Collapse (Survival Secrets That Actually Help You)

Survive The End Days (Biggest Cover Up Of Our President)